| Installation Instruction |

|

|

|

|

| Tools | Surface Preparation | Papering | Wallpaper Surface Finishing |

Tools: Palm brush, roller, spary, mixer, tank, hake brush (roller), clean cloth (2 pieces), white paper, knife. |

| Materials: wallpaper glue powder, anti-blushing agent and diluent for nitrocellulose coating. |

We recommended buyer to employ paperhangers qualified by career certification or qualified installation operator who is experienced in decoration of handcraft wallpaper to decorate the house.Please check the quality of materials applied carefully before erectionand construction. We disclaim all responsibility for damage caused by misuse. |

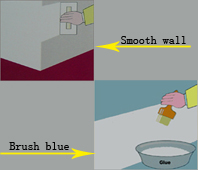

| I. Surface Preparation (Direct application on original

wall is not allowed) Applied surface should be smooth and clean, in white.As for the badly broken wall body, grit finish the wall surface into smooth and clean after the crakes and holes filled and dried. Where there is no putty layer, puttying is necessary (from interior to exterior only one kind putty could be selected and applied to avoid surface scrapes), and grit finish the wall surface into smooth and clean after dried! Keep the whole site cleaned and tidy, to prevent dust from putting on the surface to be applied during decoration. Coat uniformly fine turned anti-blushing agent which should be in used only if blended in proper specified proportion with the diluent for nitrocellulose coating, and the next process must be performed only if the layer of anti-blushing agent is dried out. |

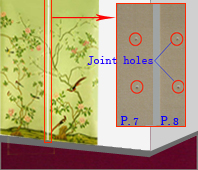

| II. Set Plumb Line Two pieces of wall patchwork we designed can be patched into one continuous pattern. Each patchwork is marked with a number at its back (a needle mark is only available on the right side of single patch, and it is only required to match the left side of the second patch in line with the needle).The patchwork marked in number 1 or holds the smallest size must be firstly hanged during decoration. The plumb line should be set at a level position or the edge of windows or doors. Hanging process should be done in accordance with the pre-designed order strictly. |

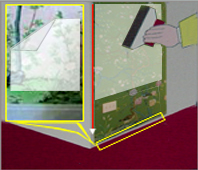

| III. Papering (i) Mix adhesives Add adhesives in proportion of Powder: Emulsion: Water = 1:1:10 into one container and mix them equally and fully with mixer. The factory mixing proportion of bought wallpaper adhesives or glue powder can be alternation, e.g. you can choose adhesives in brand of Evans Heavy Duty Cler or Golden Harvest GH14 in America. (ii) Back the paper against a level position, and spray water uniformly with a pneumatic spray to keep the paper wet and flat. (iii) Coat uniformly the adhesives mixed or fine turned wallpaper glue on the wall surface prepared to be papered with a roller, coating scope is limited into one paper size. (iv) Spray water uniformly once on the coated wall surface, fix the wet paper along the plumb line, and brush the paper from top to bottom or from left to right as well as carefully adhesive the paper into the wall with the palm brush.Parallel the patchwork edge with the plumb line.Eliminate the bulb and overlapped time to time during the operation. (v) Since papered. Used palm brush heavily the white paper as separation on the wall paper to fasten it. |

| IV. Treatments on Joints Adhesive the second patchwork following with the method above, the pattern on joints should be matched with the primer one through edgily matching the needle and pattern of primer one where the needle is available at both top and bottom. |

| V. Wallpaper Surface Finishing The silk wallpapers have been anti-dust and waterproof treated, there is no use to take any further protection measures on the surface. Mettalic wallpaper(Aluminum Silver Leaf / Clinquant) should be covered with a thin layer of water-based vanish when they are installed on wall that keep the ground color shining. |

| VI. Regular Maintenance: Keep relatively dry and away from manmade scraped. |

| VII. have any question on the installation, please email us soon, we will help you to resolve it within 24 hours. |